Pay safely and quick with iDeal

Pay safely and quick with iDeal

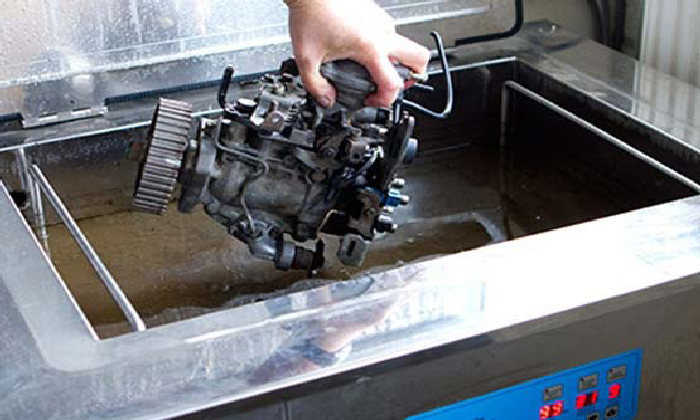

With ultrasonic cleaning, small vacuum bubbles (cavitation) are created in a liquid by ultrasonic waves. When they implode, energy is released that removes dirt from immersed pieces. Ultrasonic cleaning uses piezoceramic rings (‘transducers’). The piezoceramics convert the high-frequency electrical energy from a generator into high-frequency mechanical sound vibrations with a minimum frequency above the human hearing limit, higher than 20 kHz. The sinusoidal waves split the liquid into high and low pressure regions. Microscopically small vacuums are created in the low-pressure area. These vacuum bubbles rise up and implode in the high-pressure area. This process is called cavitation. A pressure of about 680 bar can develop in each bubble. Impurities are in effect blown away from the material by the force released by the implosion. This is comparable to the cleaning effect of an infinite number of micro-brushes. The process takes an average of half an hour. For difficult or critical processes, there is the option of using several phases (e.g. rinsing, ultrasonic cleaning, ultrasonic rinsing).

In 90% of applications, this involves degreasing metals. The technique is also used in the optical industry (degreasing glasses lenses), the graphics industry (removing ink residues from printing plates), and in the medical sector (cleaning) but also more and more for industrial applications.

The most important advantage of ultrasonic cleaning compared to conventional cleaning techniques that these vacuum bubbles can reach everywhere. It is also possible to clean very precisely. Especially for objects where other techniques fall short (e.g. nozzles or spinnerets), ultrasonic cleaning is the solution.

Because ultrasonic cleaning requires less detergent, e.g. for degreasing, this can be regarded as an environmentally friendly technique. Biodegradable products can be chosen for most applications, so waste water is also kept to a minimum. Filter systems and oil skimmers can also be installed to recover some of the liquid. When solvents are used in ultrasonic cleaning, they can be collected by specialised companies after use, so there is no environmental harm in the workshop. For example, installations can be fitted with a tap at the bottom to collect the waste water.

Other methods of removing contaminants are often intensive or require an operator to supervise the process. This is not the case with ultrasonic cleaning. When everything is ready, the installation is switched on and the ultrasonically cleaned material is taken out again after the cycle. It is therefore very easy to use.

Although not all encrusted dirt can be removed, ultrasonic cleaning permits very deep degreasing. This makes it possible to reuse pieces that would normally be thrown away because of the high level of contamination. This can be a way to achieve cost savings.

Industrial ultrasonic cleaning is not a panacea. If the contamination cannot be removed by sanding, polishing or brushing, it cannot be removed by ultrasound either! Ultrasound does not replace or improve the effect of the cleaning product but adds the mechanical processing, time and temperature (Sinner’s Circle).

Although modern ultrasonic baths are often insulated, noise pollution can still be caused by the ultrasonic frequencies, especially when used often. It is therefore recommended to use ear protection at all times when the installation is running. It is also not a luxury to respect the necessary distance from the vibrations. This prevents problems later on. Most ultrasonic cleaning baths are equipped with a cover that eliminates much of the disturbing noise. Working with an open bath is therefore out of the question. A closed bath will cause much less noise.

Certain products cannot be used for ultrasonic cleaning because of the risk of explosion. Various manufacturers are currently working on bringing Atex-compliant equipment onto the market. Elma specifies a flash point of at least 55°C If an ultrasonic cleaning bath has a thermostat, it switches off in time. There are also ultrasonic baths that can cool the liquid.

E.P. Solvex – Powerful, biodegradable cleaner for use in ultrasonic baths, spray cleaners, rinsing machines, etc. Eco Parts Cleaner – Powerful, biodegradable cleaner for use in ultrasonic baths, spray cleaners, rinsing machines etc. Flexeco Plus – Powerful, biodegradable, water-dilutable cleaning concentrate; specially developed for removing pigments, adhesives, inks and paints. Also suitable for use in the pharmaceutical and rubber industries. Can also be used in ultrasonic cleaning equipment. Liquidsolv – Powerful, biodegradable cleaner for use in ultrasonic baths, spray cleaners, rinsing machines, etc. Remosolv SE2 – Fast-acting, VOC-free rinsing agent for cleaning spray equipment used to handle paints, lacquers and coatings.